Contents

Introduction

It is crucial to understand why machine and equipment safe guards are to be used on machines. An operator or maintenance worker must be informed as to the location of the safe guards on the machines, and should also be provided information on why safe guards protect them and what hazards they protect them from.

An operator or maintenance worker also should be trained on how to remove machine and equipment safe guards from the machines and also to understand in what circumstances guards can be removed. Workers need to be trained in procedures to follow if they notice guards are damaged, missing or inadequate.

An operator or maintenance worker should be provided with a dress code. For example; no loose fitting clothing or jewelry. These items could easily be caught in the equipment or machines. From the simplest hand tool to the most complex machinery… operational safety hazards exist with any equipment.

The Machine Guard Program is designed to protect Employees from hazards of moving machinery. All hazardous areas of a machine shall be guarded to prevent accidental “caught in” situations. References: General Requirements for all

- Machines (29 CFR 1910.212),

- Woodworking Machinery (29 CFR 1910.213),

- Abrasive Wheels (29 CFR 1910.215),

- Power Presses (29 CFR 1910.217),

- Power Transmission (29 CFR 1910.219).

Machine & Equipment Hazards:

Electrical Hazards – equipment that uses electricity as a power source is a potential electrocution hazard. Check power cords, switches and connections for exposed wires or broken parts.

Amputation & Caught-in Hazards – machine guards on equipment are installed to protect our employees from moving parts. Of course if they have been removed during maintenance or adjustment they will no longer provide protection. Check equipment every day to ensure that all guards are in place.

Chemical Hazards – processing equipment that uses chemicals can be sources of numerous hazards. Leaks can cause slip hazards as well as possible exposure to harmful chemicals. Hoses that leak could create a respiratory problem from vapors.

Sharp Edges – simply walking past machinery may be hazardous if sharp edges are not guarded check equipment mounting brackets, sign edges and control boxes to see if sharp edges are present.

Eye Hazards – tools and equipment that create chips, sparks or dust are potential eye hazards. These types of eye hazards are generally controlled by safety glasses, goggles and face shields. Check eye protection your workers use to make sure they are not broken, scratched and are the correct type for the hazard. As a minimum, anyone who uses hand or power tools should wear safety glasses.

PPE – personal protective equipment should be considered a secondary line of defense against equipment hazards. Employees need to know how to properly select, use and clean any PPE they use. PPE does wear out and has limitation on the level of protection against hazards – your workers should know these limitations.

Definition of Terms:

1. Guards: Barriers that prevent Employees from contact with moving portions or parts of exposed machinery or equipment which could cause physical harm to the Employees.

2. Enclosures: Mounted physical barriers which prevent access to moving parts of machinery or equipment.

3. Point-of-Operation: The area on a machine or item of equipment, where work is being done and material is positioned for processing or change by the machine.

4. Power Transmission: Any mechanical parts which transmit energy and motion from a power source to the point-of-operation. Example: Gear and chain drives, cams, shafts, belt and pulley drives and rods. NOTE: Components which are (7) feet or less from the floor or working platform shall be guarded.

5. Nip Points: In-Running Machine or equipment parts, which rotate towards each other, or where one part rotates toward a stationery object.

6. Shear points: The reciprocal (back and forth) movement of a mechanical part past a fixed point on a machine.

7. Rotating Motions an exposed mechanism are dangerous unless guarded. Even a smooth, slowly rotating shaft or coupling can grasp clothing or hair upon contact with the skin and force an arm or hand into a dangerous position. Affixed or hinged guard enclosure protects against this exposure.

8. Reciprocating: Reciprocating motions are produced by the back and fourth movements of certain machine or equipment parts. This motion is hazardous, when exposed, offering pinch or shear points to an Employee. A fixed enclosure such as a barrier guard is an effective method against this exposure.

9. Transverse Motions: Transverse motions are hazardous due to straight line action and in-running nip points. Pinch and shear points also are created with exposed machinery and equipment parts operating between a fixed or other moving object. A fixed or hinged guard enclosure provides protection against this exposure.

10. Cutting Actions: Cutting action results when rotating, reciprocating, or transverse motion is imparted to a tool so that material being removed is in the form of chips. Exposed points of operation must be guarded to protect the operator from contact with cutting hazards, being caught between the operating parts and from flying particles and sparks.

11. Shearing Action: The danger of this type of action lies at the point of operation where materials are actually inserted, maintained and withdrawn. Guarding is accomplished through fixed barriers, interlocks, remote control placement (2 hand controls), feeding or ejection.

Hazards:

Use of machinery or equipment with inadequate guards or damaged controls can result in:

- Amputation

- Skin Burns

- Cuts & fractures

- Death

Hazard Controls:

controls used to prevent exposure to moving or energized machine parts includes:

- Machine guards

- Interlocks

- Presence sensing devices

- Gates

- Two-hand controls

- Employee training

Machine Guarding Requirements:

1. Guards shall be affixed to the machine where possible and secured.

2. A guard shall not offer an accident hazard in itself.

3. The point-of-operation of machines whose operation exposes an Employee to injury shall be guarded.

4. Revolving drums, barrels and containers shall be guarded by an enclosure which is interlocked with the drive mechanism.

5. When periphery of fan blades are less than 7 feet above the floor or working level the blades shall be.

Machinery and equipment hazards:

Hazards created by machinery and equipment can be classified as mechanical and non-mechanical.

Mechanical hazards

Recognizing mechanical hazards

A good way to recognize mechanical hazards is to observe how the moving parts of a machine operate and how parts of a worker’s body are likely to come into harmful contact with them.

Machine parts generally move in one of three ways: they rotate, they slide, or they can rupture, fragment, and/or eject.

- Single rotating parts, such as shafts or couplings, present a risk of snagging or entanglement. Two or more parts rotating together, such as feed rolls and V-belt and pulley drives, create nip points(see Figures 1.1 and 1.2).

- Parts that slide or reciprocate, such as dies in punch presses, create shearing or crushing hazards.

- Parts that can rupture or fragment, such as an abrasive wheel, may cause impact injuries.

Figures 1.1 to 1.5 illustrate common mechanical hazards where hands, limbs, hair, clothing, and sometimes the entire body can be injured from harmful contact with unguarded moving machine parts. The illustrations show typical cases, not all possibilities.

Principal mechanical components of machinery .Most machines have three principal components:

- A power source (often an electrical motor)

- A power train that transfers moving energy

- Tooling

Hazards from these components generally involve the following:

- Power transmission parts. These are the moving parts of the power train. They usually consist of belts, pulleys, chains, sprockets, gears, shafts, and couplings. Many of the moving parts illustrated in Figures 1.1 and 1.2 are power transmission parts.

- Point of operation. This is where the tooling of the machine is contained and the machine’s work is performed. The term “feed point”is sometimes used to describe the working area of the machine.

The types of machine components and drives shown in Figures 1.1 to 1.5 are very common in most industrial operations. They account for a large number of serious injuries in the workplace.

Figure 1.1. Single rotating parts presenting a snagging/entanglement hazard.

(A) Snagging hazard from projecting flange bolts on rotating coupling.

(B) Snagging hazard from projecting key way and set screw on rotating shaft.

Figure 1.2. Multiple rotating parts presenting an in-running nip point hazard.

(A) V-belt and pulley drive: a common source of in-running nip points on powered industrial machinery. (B) Typical chain-sprocket drive. (C) Typical exposed gears. (D) Typical feed rolls.

Figure 1.3. Combination of rotating and sliding parts and reversing parts, creating two

in-running nip point hazards.

(A) Rack and pinion gears. (B) Conveyor belt spool.

Figure 1.4. Sliding/pivoting movement creating struck by/crushing hazards.

(A) Sliding milling table striking worker in abdomen.

(B) Sliding milling table crushing worker against adjacent wall.(C) Worker struck by robot arm.

(D) Scissor lift creating crushing/shearing hazards

Figure 1.5. Hazards from fragments and projectiles.

(A) Fragments from exploding abrasive wheel. (B) Projectile from pneumatic nail gun.

Health hazards:

Workers operating and maintaining machinery can suffer adverse effects other than physical injury caused by moving parts. They can be exposed to hazards through inhalation, ingestion, skin contact, or absorption through skin. For example, without adequate safeguards, control measures, and personal protective equipment, a worker may be at risk of occupational disease resulting from exposure to:

- Toxic or corrosive chemicals that can irritate, burn, or pass through the skin

- Harmful airborne substances that can be inhaled, such as oil mist, metal fumes, solvents, and dust

- Heat, noise, and vibration

- Ionizing radiation such as X-rays and gamma rays

- Non-ionizing radiation such as ultraviolet light (UV), radio frequency (RF) energy, and lasers

- Biological contamination and waste

- Soft tissue injuries (for example, to the hands, arms, shoulders, back, or neck) resulting from repetitive motion, awkward posture, extended lifting, and pressure grip

Other hazards

- Some hazards are associated with things other than moving parts:

- Slips and falls from and around machinery during maintenance

- Unstable equipment that is not secured against falling over

- Fire or explosion

- Pressure injection injuries from the release of fluids and gases under high pressure

- Electrocution from faulty or ungrounded electrical components

What is a safeguard:

A safeguard is a solution or a combination of solutions that eliminate or reduce the risk of exposure to hazardous moving parts or other harmful conditions. Safeguards range from fixed barrier guards (most effective) and safeguarding devices to safe work procedures and personal protective equipment (least effective) (see the hierarchy of safeguarding solutions on below). A comprehensive risk assessment will determine which safeguards are most effective.

Hierarchy of safeguarding controls:

When selecting a safeguard or a combination of safeguards, always start at the top of the hierarchy shown below. Choose a less effective safeguard only when the more effective solution is impracticable. For example, you may be able to eliminate the need to hand-feed a machine by installing an automated feeder. Installing a fixed barrier guard across a feed point may be practicable if the feed stock is a flat sheet metal blank; for larger material, you may have to allow access

to the point of operation using two-hand controls or a light curtain (a presence-sensing device) instead.

Classification of safeguards:

There are six general ways to safeguard machinery and equipment:

- Barrier guard

- Safeguarding devices

- Location

- Awareness means

- Training and procedures

- Personal protective equipment

Barrier guards:

Properly designed and installed barrier guards provide the most effective protection to workers. Fixed barrier guards are the first choice of engineering control to keep workers from contacting hazardous moving parts or to contain harmful fluids and projectiles, particularly when access is not normally required during operation. Fixed barrier guards must be secured with at least one fastener requiring a tool for removal.

When a barrier guard must be moved aside to enable a worker to access a point of operation or feed point during normal production work, the guard must be interlocked to disable the control system until the guard is put back in place and the control system is reset. Some barrier guards are adjustable to allow materials of varying thickness to be fed into a machine. Some guards are attached to the tooling or dies that fit into a machine. These are a special type of barrier guard called die enclosure guards.

A common requirement of all barrier guards is that they prevent a worker from reaching around, over, under, or through the guard to the danger area.

Safeguarding devices:

Access to feed points and ejection of formed parts is often required during normal machine operation. This may make the use of a fixed barrier guard, or even an interlocked guard, impracticable. Fortunately there are a number of safeguarding devices that can provide a high

level of protection to workers.

These devices generally operate in one or a combination of ways:

- Requiring the operator to remove his or her hands or entire body from the danger area before the machine can be cycled. Two-hand controls and interlocked gate guards function this way.

- Stopping the machine if the operator or another worker enters the danger area while the machine is cycling. Presence-sensing devices such as light curtains and photoelectric devices and pressure sensitive mats function this way. These devices depend for their effectiveness on a very reliable braking system and associated control system.

- Physically restraining the operator from reaching into the danger area of the machine at any time. This can be done through the use of a restraint device such as a safety belt and lanyard.

- Involuntary tripping or activation of an emergency stop device if all or part of a worker’s body approaches or enters the danger area. Examples include a “crash bar” or “belly bar” in front of a trim.saw in-feed lug chain; the emergency contact bar in front of the in running feed rolls of a flat work ironer; and the emergency trip wire installed along a conveyor system.

- Limiting machine movement or travel to a safe range or speed. Examples include operating the machine in a “jog,” “inch,” or “setup” mode, activated by special control buttons (printing presses); limiting die movement to 6 mm (¼ inch) or less before a piece can be inserted into the dies; an anti-repeat device that prevents a machine from performing more than one cycle (single stroke mode).

- Locating the worker in a safe place before the machine can be started. Examples include a foot control fastened to the floor a safe distance from the machine (called “captive” or “hostage” control); the activating control for an X-ray machine located in an isolated room.

- “Hold-to-run controls,” which require the operator to keep the control activated in order for the machine to continue to operate (also known as “dead man” or “operator-maintained” controls).

- “Captive key systems,” which use a series of keys and locks to start or shut down a hazardous operation in a prescribed and safe sequence.

Safeguarded by location:

Machinery may be safeguarded by location if the distance to dangerous moving parts is greater than 2.4 meters (8 feet) from any floor, walkway, access platform, or service ladder. Any work on the machine must be performed using lockout.

Warning devices:

Some machine hazards cannot be practicably safeguarded using the methods described above. In these cases, less effective means may have to be used to minimize or reduce the danger to workers. These may include such devices as splash shields; flashing lights, strobes, and beacons; audible warning devices such as beepers, horns, and sirens; warning signs, decals, and barrier chains and ropes to restrict access. You will need to consider the work environment and layout to determine whether these measures will be effective.

Training, supervision, and procedures:

Also known as administrative controls, training, supervision, and procedures are near the low end of the hierarchy of protection because their effectiveness depends on human factors such as adequate training and supervision. Lockout is an example of such a procedure.

Personal protective equipment:

Personal protective equipment may have to be used even when other machine hazards are effectively safeguarded. In some cases, such as operating a powered forging hammer, the only protection available to the operator, besides training and safe work procedures, may be eye and face protection, hearing protection, and hand protection.

Barrier guards:

Typical barrier guards

Figures 3.1 to 3.3 show examples of typical barrier guards.

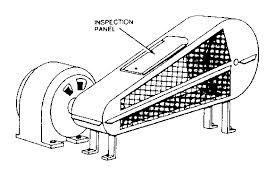

Figure 3.1. Fixed power transmission guard.

Figure 3.2. Adjustable guards.(A) Adjustable band saw guard. (B) Adjustable power press feed guard.

Figure 3.3. Handheld circular saw guard, an example of a self-adjusting (self-retracting) guard. Guardsdesigned for right-handed people can sometimes cause problems for those who are left handed. A lefthandedperson often has difficulty operating a handheld circular saw.

Design and performance requirements for barrier guards:

Barrier guards are the preferred means of safeguarding when access is not required during normal operation.

Fixed barrier guards must:

- Prevent access to the danger area from all directions

(AUTO: around, under, through, over)

- Not create additional pinch points or other hazards .

- Safely contain broken parts (such as belts and chains).

- Be secured by at least one fastener requiring a tool for removal,unless properly interlocked with the machine control system.

- Allow for safe lubrication and minor adjustments.

Fixed barrier guards should:

- Offer good visibility to feed points.

- Stand up to normal wear and tear.

- Meet normal production and quality needs.

- Be difficult to modify or defeat.

Point-of-operation (feed) guards: maximum permissible openings:

Point-of-operation guards (also known as feed guards) are often designed with horizontal members to enable the operator to insert flat stock into the machine. Figure 3.5 shows how the openings between the horizontal guarding members decrease as the worker’s fingers come closer to the pinch point.

Hand-feeding equipment usually presents the highest risk of injury to a worker. Feed guards must be carefully designed to ensure that theworker’s hands cannot access the danger point. Table 3.1 and Figure 3.5give the necessary clearances for an effective point-of-operation guard with a horizontal slotted feed opening.

Table 3.1. Maximum permissible openings in point-of-operation guards based on distance to hazard.

Figure 3.5. Visual representation of Table 3.1.

Safeguarding devices

Typical safeguarding devices:

Figures 3.7 to 3.12 show examples of typical safeguarding devices.

Figure 3.7. Two-hand controls.

(A) Two-hand controls – power press. The press will not cycle unless bothrun buttons are activated using both hands within a certain time period of each other.

(B)Two-handcontrol levers – paper guillotine shear. The shear will not cycle unless both levers are activated, whichrequires the use of both hands within a certain time period of each other.

Figure 3.8. Light curtain or similar photoelectric sensing device.

(A) Light curtain – brake press.The press is operated in the normal manner using the foot control. It will stop if hands enter the light beam-protected zone.

(B) Light curtain – access to robotic cell. The robot is deactivated if a person enters the doorway protected by a light curtain safeguarding device.

Figure 3.9. Interlocked guard. The interlocked door must be closed before the machine can be started.

Figure 3.10. Pullback and restraint devices (not in common use).

(A) Press operator using pullback devices.The operator’s hands are pulled away by cables if the operator leaves them in the danger area.

(B) Brake press operator using fixed restraint devices. The operator’s hands cannot reach the danger area; hand tools would be required for access.

Figure 3.11. Emergency contact or tripping device in the form of an emergency “belly bar” on a calender.

The operator cannot reach into the in-running feed rolls without automatically activating the machine’s emergency stop bar.

Figure 3.12. Pressure-sensitive safety mat safeguarding access to machine.

The machine will come to an emergency stop if anyone, including the operator, steps on the mat.

Design and performance requirements for presence-sensing devices:

How it is work:

Unlike barrier guards and two-hand controls, presence-sensing devices do not prevent access to a hazardous point of operation. However, they prevent dangerous machine motion if any part of a worker’s body is in the danger area when a machine cycle is initiated. They are a good choice of safeguard when frequent access is required for loading parts and making adjustments during normal operation and physical guarding is too restrictive. These safety devices prevent dangerous motion while permitting unrestricted access by sensing the presence of the operator and sending a stop signal. Examples include light curtains, proximity sensors, and safety mats.

There are many technical factors, such as machine control reliability and safety distance, that affect the proper selection and positioning of light curtains, proximity sensors, and safety mats. Refer to the following:

standards referred to in the Occupational Health and Safety Regulation:

- CSA Standard Z432, Safeguarding of Machinery.

- CSA Standard Z142, Code for Punch and Brake Press Operation: Health,Safety and Guarding Requirements.

- CSA Standard Z434, Industrial Robots and Robot Systems – General Safety Requirements

Photoelectric light curtains:

These devices emit a “curtain” of harmless infrared light beams in front of the hazardous area. When any of the beams is blocked, the light curtain control circuit sends a stop signal to the machine’s control system. This type of safeguard offers the maximum protection with the minimum impact on normal machine operation. It is particularly well suited to safeguarding brake press operations. Note: steam or dust can inadvertently affect a light curtain.

Pressure-sensitive safety mats:

These devices are used to guard the floor area around a machine. A matrix of interconnected mats is laid around the hazard area, and the proper amount of pressure (such as an operator’s footstep) will cause the mat control unit to send a stop signal to the guarded machine. Pressure sensitive mats are often used within an enclosed area containing several machines, such as flexible manufacturing or robotics cells. When access into the cell is required (for example, in the case of robot “teaching”), the mats prevent dangerous motion if the operator strays from the safe area.

Design and performance requirements for safety interlocks

Horizontal injection molding machine with interlocked gate guard

How it is work:

If access to a point of operation (a feed point) is required during normal operation, a movable open able barrier guard interlocked with the machine’s power source can be a reliable and cost-effective solution. The control power for the machine is routed through the safety contact of the interlock. The interlock ensures that the machine will not operate if the guard is in the open position. The power source for the machine is usually electrical, but it could also be pneumatic or hydraulic.

If the interlocked guard can be opened during operation, the machine will stop. This is called simple interlocking. Some interlock switches also have a locking device that locks the guard door closed and will not release it until the machine comes to a safe stop. The feature is found in some households’ spin cycle washing machine. It is referred to as power interlocking. It is used with machinery such as tumblers and centrifuges, where the coasting down time may take several seconds to several minutes.

Movable gate:

A unique safeguarding application using interlocking is the movable gate device. It is commonly used to provide protection to an operator when hand-feeding parts into a punch press, but it can be applied tovarious other machines. See Figure 3.13.

Figure 3.13. Movable interlocked gate mounted on a punch press.

When the machine completes its cycle or returns to top of stroke (in the case of a power press), the gate automatically opens, allowing the operator to remove the formed part. The operator then places a feed stock (blank) into the machine and activates the controls to start another cycle. This can be done with either a foot control, a single hand control, or even two-hand controls (preferred). The gate must close before the machine can cycle. A low-pressure air cylinder attached to the gate performs this closing function. If there are any obstructions under the gate (such as the operator’s hands), the gate will not fully close. The interlock switch will prevent further machine operation until the obstruction has been removed and the controls reset.

Shields and awareness barriers:

How it is work

Shields, usually in the form of transparent barriers, are typically installed on lathes, milling machines, boring machines, and drill presses. They can also be used on woodworking machines. They are generally intended to deflect chips, sparks, sward, coolant, or lubricant away from the operator and other workers in the machine area. Besides providing some protection as a barrier, most shields also provide good visibility into the point of operation.

Awareness barriers include installations such as electrically interlocked pull cable assemblies installed in the rear area of machines such as brake presses and shears to restrict worker entry. These areas are often out of the operator’s view. The machine is stopped if someone pulls or loosens the cable. It is recommended that a sign denoting the danger be placed on the pull cable.

Although shields and awareness barriers offer some degree of safeguarding, they cannot be considered guards because they only restrict but do not prevent access to the danger area.

When installing these devices and before moving them from their normally applied position, always turn off power to the machine; follow lockout procedures if there is a risk of accidental startup.

Safeguarding by location:

With the body upright and standing at full height, the safe clearance when reaching upward to an unguarded hazard is a minimum of 2.5 metres (8 feet) (see Figure 3.16). Any hazardous moving parts beyond this distance are considered to be guarded by location. If access to hazardous locations is gained by use of ladders, scaffolds, and so on, temporary guarding or lockout procedures must be used.

Click the following link to download