Slips, trips, and falls constitute the majority of general industry accidents. They cause 15% of all accidental deaths, and are second only to motor vehicles as a cause of fatalities. Active participation by management, supervisors and employees is necessary to prevent hazardous conditions that could result in slips, trips or falls.

Simple Housekeeping methods can prevent slip-trip-fall hazards:

Load rating limits shall be marked on plates and conspicuously posted. It shall be unlawful to place, or cause, or permit to be placed, on any floor or roof of a building or other structure, a load greater than that for which such floor or roof is approved.

Floor openings and holes, wall openings and holes, and the open sides of platforms may create hazards. People may fall through the openings or over the sides to the level below. Objects, such as tools or parts, may fall through the holes and strike people or damage machinery on lower levels.

Standard railings shall be provided on all exposed sides of a stairway opening, except at the stairway entrance. For infrequently used stairways, where traffic across the opening prevents the use of a fixed standard railing, the guard shall consist of a hinged floor opening cover of standard strength and construction along with removable standard railings on all exposed sides, except at the stairway entrance.A “standard railing” consists of top rail, mid rail, and posts, and shall have a vertical height of 42 inches nominal from the upper surface of top rail to floor, platform, runway, or ramp level. Nominal height of mid rail is 21 inches.A “standard toe board” is 4 inches nominal in vertical height, with not more than ¼-inch clearance above floor level.Floor openings may be covered rather than guarded with rails. When the floor opening cover is removed, a temporary guardrail shall be in place, or an attendant shall be stationed at the opening to warn personnel.

Every floor hole into which persons can accidentally walk shall be guarded by either

Every open-sided floor or platform 4 feet or more above adjacent floor or ground level shall be guarded by a standard railing on all open sides, except where there is an entrance to a ramp, stairway, or fixed ladder. The railing shall be provided with a toe board wherever, beneath the open sides:

Every runway shall be guarded by a standard railing, or the equivalent, on all sides 4 feet or more above floor or ground level. Wherever tools, machine parts, or materials are likely to be used on the runway, a toe board shall also be provided on each exposed side.

Every flight of stairs with four or more risers shall have standard stair railings or standard handrails as specified below. Stair width is measured clear of all obstructions except handrails.

A “standard stair railing” (stair rail) shall be of construction similar to a standard railing, but the vertical height shall be not more than 34 inches nor less than 30 inches from the upper surface of the top rail to the surface of the tread in line with the face of the riser at the forward edge of the tread.

Fixed Industrial Stairs shall be provided for access to and from places of work where operations necessitate regular travel between levels. Requirements include:

The chief hazard when using a ladder is falling. A poorly designed, maintained, or improperly used ladder may collapse under the load placed upon it and cause the employee to fall. A ladder is an appliance consisting of two side rails joined at regular intervals by crosspieces on which a person may step.

A smooth, even, flat surface is ideal for walking because it reduces the likelihood of twisted ankles or loss of balance which can lead to falls and other painful mishaps. In fact, guidelines require that parking areas be level and even, with cracks, holes and lumps not exceeding 1 cm.

However, heavy use by both pedestrians and vehicle traffic both cause a parking surface to deteriorate. Figure 1 shows examples of damage to look for: broken pavement, and gratings.

Figure 1

Leaks and spills of engine oil or antifreeze, which commonly occur wherever cars are parked, can further add to risks of slips and falls.

In outdoor parking lots, severe weather conditions additionally aggravate even slight damage to the parking surface. As a consequence the risk for falls due to slips and trips is relatively high in this environment.

Speed bumps and tire stops are usually not necessary in a well-designed parking lot. Besides potentially causing damage to vehicles, they create a yet another hazard for tripping – see Figure 2.

Figure 2

The layout of the parking area should make it impossible to drive unsafely or fast.

Otherwise, if speed bumps or tire stops are absolutely necessary:

Falls can be prevented through a number of steps:

Figure 5

Good housekeeping includes:

Figure 6

Figure 1 shows the recommended dimension ranges for all the important elements of stairways.

Figure 1

A – Optimal range: 30º-35º

B* – Handrail height: 80-96.5 cm

C* – Riser height: 12.5-20 cm

D* – Step width: 90 cm min.

E* – Tread depth: 23.0-35.5 cm

Within a staircase, treads shall have a uniform run and tread depth that does not vary more than 0.6 cm*.

* Values are from the National Building Code of Canada (2005). Always check with your local jurisdiction as requirements are different in each area.

The maximum range for a stair slope is 20º-50º. However, because the majority of people prefer a slope of 30º-35º, this is the recommended range.

Steeper stairs change the way you climb them because the steeper they are the more effort you exert. The ratio of riser height and tread depth has to be adjusted accordingly. (See Figures 2 and 3)

Figure 2

Figure 3

From: Kodak’s ergonomic design for people at work. 2nd ed. John Wiley & Sons, 2004. p.244

The dimension of risers or treads in a stairway should not vary more than 1 cm. When doors open directly into the stairwell, a 50 cm-wide platform should be provided beyond the swing of the door. The recommended maximum number of steps between landings is 18, with no more than two flights without a change of direction. The depth of any landing should be at least equal to the width of the stairs.

To reduce the risk of slipping on stairs, non-slippery surface on the whole steps or at least on the leading edges is crucial. Such a surface can be made of rubber, or metal or painted with special slip-resistant paint. Regular maintenance of the stairs in good repair plus good housekeeping can reduce hazards for tripping.

Attempts to design aesthetically pleasing stairways including handrails must not compromise functionality.

The prime function of the handrail is for holding as support while going up or down stairs.

It is therefore crucial to be able to grasp it quickly, easily and firmly if you should start losing your balance.

Figure 4 shows the recommended cross-section and dimensions of a good handrail. Ideally the cross-section should be round (diameter 4-5 cm, with circumference of 12-14 cm) to allow for a good firm grip.

Figure 4

You should be able to run your hand smoothly along the entire length without having to adjust your grip. You should apply the so-called “tennis-racket grip” at all times when possible.

Guardrails of at least 40 cm above the surface of the stairs are needed to prevent falls off the side of the stairs that are not equipped with a banister.

Improving visibility on stairs significantly reduces the risk for common mishaps caused by misjudging distances. Otherwise you can trip on a step or miss it completely. You can catch a heel on the edge of a step. Such mishaps are a routine cause of twisted ankles, sprained knees or more serious injuries incurred by a total fall.

Good housekeeping is also vital to stair safety:

Click the below link to know more details guidelines and forms

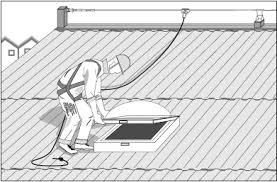

Working at HeightsDifferent types of Height work permit system

WAH-sample-1 WAH-sample-2 WAH-sample-3 WAH-sample-4 WAH-sample-5 WAH-sample-6 WAH-sample-7 WAH-sample-8 WAH-sample-9 WAH-sample-10Note : WAH stands for Working At Height

Click the below links to know more details

Tool Box talks- Fall Protection

Every year nearly 100 fatalities and 10,000 injuries occur world over on scaffolds despite numerous safety regulations aimed to prevent such incidents. If you work on scaffolding, you must be able to recognize the hazards associated with the type of scaffold you are using, and know what to do when you recognize something that just isn’t safe. There are a number of different scaffold types, having different rules and regulations surrounding their assembly, fall protection requirements, & inspection procedures.

An estimated 2.3 million construction workers, or 65% of the construction industry, work on scaffolds frequently. Protecting these workers from scaffold-related accidents would prevent 4,500 injuries & 75 deaths every year, at a savings for employers of $90 million in workdays not lost. In a recent BLS study, seventy-two percent of workers injured in scaffold accidents attributed the accident either to the planking or support giving way, or to the employee slipping or being struck by a falling object. All of these can be controlled by compliance with Building and Other Construction Workers (Regulation of Employment and Condition of Service) Act, 1996 and Central Rules, 1998.

A scaffold is a temporary structure specifically erected to support access or working platforms. Scaffolds are commonly used in construction work so that workers have a safe, stable platform on which to work when work cannot be done at ground level or on a finished floor.

Scaffolds, once properly erected, are a control measure to prevent the risk of persons and objects falling when working at height.

Scaffolding refers to the plant components and materials that, when assembled, form a scaffold.

Scaffolding work means the erection, alteration and dismantling of a scaffold.

Scaffolding work that involves scaffold from which a person or object could fall more than four meters is classified as ‘high risk work’ under the WHS Regulations for which a license is required.

Some examples of the hazards associated with work involving the erection, use, maintenance, alteration and dismantling of scaffolds include:

When assessing risks relating to scaffolds you should consider things such as:

The ways of controlling risks are ranked from the highest level of protection and reliability to the lowest. This ranking is known as the hierarchy of control measures. The duty holder must always aim to eliminate a hazard first. If this is not reasonably practicable, the risk must be minimized by using one or more of the following:

If risk remains it must be minimized by implementing administrative controls, so far as is reasonably practicable. For example store scaffolding components as close as practical to the work area in order to minimize the distance over which loads are manually moved. Clear access ways should also be ensured so that materials and equipment can be easily accessed.

Any remaining risk must be minimized with suitable personal protective equipment (PPE), such as providing workers with hard hats, hearing protectors and high visibility vests.

There are many different types of scaffolds used . The three major categories are:

Supported scaffolds consist of one or more platforms supported by outrigger beams, brackets, poles, legs, uprights, posts, frames, or similar rigid support. Because frame scaffolds are the most common type of supported scaffold.

The types of self-supporting scaffolds include:

Suspended scaffolds are platforms suspended by ropes, or other non-rigid means, from an overhead structure. Because two-point scaffolds are the most common type of suspended scaffold.

Special use scaffolds and assemblies are capable of supporting their own weight and at least 4 times the maximum intended load. The types of special use scaffolds include:

Supported scaffolds consist of one or more platforms supported by outrigger beams, brackets, poles, legs, uprights, posts, frames, or similar rigid support. Because frame scaffolds are the most common type of supported scaffold.

Fabricated frame scaffolds are the most common type of scaffold because they are versatile, economical, and easy to use. They are frequently used in one or two tiers by residential contractors, painters, etc., but their modular frames can also be stacked several stories high for use on large-scale construction jobs. NOTE: Except where indicated, the same basic scaffold requirements that appear in this module also apply to manually propelled, pump jack, ladder jack, tube and coupler, and pole scaffolds, as well as the specialty scaffolds described in Supported Scaffolds. Additional requirements for these scaffolds can be found in their respective modules. The number one scaffold hazard is worker falls. Fall protection consists of either personal fall-arrest systems or guardrail systems, and must be provided on any scaffold 10 feet or more above a lower level. Specific requirements are described below.

Mobile scaffolds are a type of supported scaffold set on wheels or casters. They are designed to be easily moved and are commonly used for things like painting and plastering, where workers must frequently change position.Scaffolds must be plumb, level, and squared.All brace connections must be secured.To prevent movement of the scaffold while it is being used in a stationary position, scaffold casters and wheels must be locked with positive wheel locks Platforms must not extend beyond the base supports of the scaffold, unless stability is ensured by outrigger frames Leveling of the scaffold, where necessary, must be achieved by the use of screw jacks.

Pump jacks are a uniquely designed scaffold consisting of a platform supported by move able brackets on vertical poles. The brackets are designed to be raised and lowered in a manner similar to an automobile jack. Pump jacks are appealing for certain applications because they are easily adjusted to variable heights, and are relatively inexpensive.Pump jack brackets, braces, and accessories must be fabricated from metal plates and angles.Each pump jack bracket must have two positive gripping mechanisms to prevent any failure or slippage. When bracing already installed has to be removed so the pump jack can pass, an additional brace must be installed approximately 4 feet above the original brace before it is removed. The additional brace must be left in place until the pump jack has been moved and the original brace reinstalled.

Tube and coupler scaffolds are so-named because they are built from tubing connected by coupling devices. Due to their strength, they are frequently used where heavy loads need to be carried, or where multiple platforms must reach several stories high. Their versatility, which enables them to be assembled in multiple directions in a variety of settings, also makes them hard to build correctly. When platforms are being moved to the next level, the existing platform must be left undisturbed until the new bearers have been set in place. Braced before receiving the new platform.The use of couplers made from gray cast iron is prohibited. Tube and coupler scaffolds over 125 feet in height must be designed by a registered professional engineer.

A ladder jack scaffold is a simple device consisting of a platform resting on brackets attached to a ladder. Ladder jacks are primarily used in light applications because of their portability and cost effectiveness. All ladders used to support ladder jack scaffolds must comply with-Stairways and Ladders. Ladder jacks must be designed and constructed to bear on the side rails and ladder rungs. Ladders used to support ladder jack scaffolds must be placed to prevent slipping fastened to prevent slipping and or equipped with devices to prevent slipping.

Pole scaffolds are a type of supported scaffold in which every structural component, from uprights to braces to platforms, is made of wood. OSHA has standards for two kinds: single-pole, which are supported on their interior side by a structure or wall, and double-pole, which are supported by double uprights independent of any structure.Because they have to be built from scratch and cannot easily be reused, pole scaffolds are considered old-fashioned and are rarely used today.When platforms are moved to the next level, the existing platform must be left undisturbed until the new bearers have been set in place and braced. Pole scaffolds over 60 feet in height must be designed by a registered professional engineer.

Many scaffold types regulated by OSHA standards are rarely used, and designed for a very narrow and specific range of applications. Requirement for these specialty scaffolds are addressed on this page. Scaffolds must not be more than 10 feet or two tiers in height, whichever is less.Scaffold platforms must be placed no higher than the second-highest rung or step of the ladder supporting the platform.

Suspended scaffolds are platforms suspended by ropes, or other non-rigid means, from an overhead structure. Because two-point scaffolds are the most common type of suspended scaffold.

A catenary scaffold is a scaffold consisting of a platform supported by two essentially horizontal and parallel ropes attached to structural members of a building or other structure.Platforms supported by wire rope must have hook-shaped stops on each of the platform to prevent them from slipping off the wire ropes. These hooks must be positioned so that they prevent the platform from falling if one of the horizontal wire ropes breaks. Wire ropes must not be over-tightened to the point that a scaffold load will overstress them. Wire ropes must be continuous and without splices between anchors.Each employee on a catenary scaffold must be protected by a personal fall-arrest system.

An interior hung suspension scaffold consists of a platform suspended from the ceiling or roof structure by fixed-length supports.Interior hung scaffolds must be suspended from roof structures (e.g., ceiling beams).Roof structures must be inspected for strength before scaffolds are erected.Suspension ropes/cables must be connected to overhead supports by shackles, clips, thimbles, or equivalent means.

A multi-point adjustable scaffold consists of a platform (or platforms) suspended by more than two ropes from overhead supports and equipped with means to raise and lower the platform(s) to desired work levels. An example of this type of scaffold is a chimney hoist, used in chimney-cleaning operations.Multi-point adjustable scaffolds must be suspended from metal outriggers,brackets,wire rope slings,hooks or means that meet equivalent criteria for strength, durability, etc.When two or more scaffolds are used they must not be bridged together unless design allows them to be connected,bridge connections are articulated and hoists are properly sized.

A single-point adjustable scaffold consists of a platform suspended by one rope from an overhead support and equipped with means to permit the movement of the platform to desired work levels. The most common among these is the scaffold used by window washers to clean the outside of a skyscraper (also known as a boatswain’s chair).The supporting rope between the scaffold and the suspension device must be kept vertical unless designed by a qualified person, accessible to rescuers,protected from rubbing during direction changes.

A float, or ship, scaffold is a suspension scaffold consisting of a braced platform resting on two parallel bearers and hung from overhead supports by ropes of fixed length.Platforms must be supported by and securely fastened to a minimum of two bearers extending at least 6 inches beyond the platform on both sides.open connections must not allow the platform to shift or slip.When only two ropes are used with each float Ropes must be arranged to provide four ends that are securely fastened to overhead supportsand Each employee on a float (ship) scaffold must be protected by a personal fall-arrest system.

A multi-level scaffold is a two-point or multi-point adjustable suspension scaffold with a series of platforms at various levels resting on common stirrups.Multi-level suspended scaffolds must be equipped with additional independent support lines that are equal in number to the number of points supported,equal in strength to the suspension ropes and rigged to support the scaffold if the suspension ropes fail. Independent support lines and suspension ropes must not be anchored to the same points. Supports for platforms must be attached directly to support stirrups (not to other platforms).

This simple type of scaffold consists of a platform suspended from needle beams, usually attached on one end to a permanent structural member. Scaffold support beams must be installed on edge.Ropes or hangers must be used for supports. Ropes must be securely attached to needle beams. Support connections must be arranged to prevent the needle beam from rolling or becoming displaced.Platform units must be attached by bolts or equivalent means. Cleats and overhang are not considered adequate means of attachment.

Two-point adjustable suspension scaffolds, also known as swing-stage scaffolds, are perhaps the most common type of suspended scaffold. Hung by ropes or cables connected to stirrups at each end of the platform, they are typically used by window washers on skyscrapers, but play a prominent role in high-rise construction as well. The safe use of a suspended scaffold begins with secure anchorage. The weight of the scaffold and its occupants must be supported by both the structure to which it is attached and by each of the scaffold components that make up the anchorage system.Adjustable suspension scaffolds are designed to be raised and lowered while occupied by workers and materials, and must be capable of bearing their load whether stationary or in motion.Because the platform is the work area of a suspended scaffold, an inspection requires safety checks of both the platform structure and how the platform is used by the workers. Even if a suspended scaffold has been assembled in compliance with every applicable standard, employers and workers must continue to exercise caution and use sound work practices to assure their safety. Extreme weather, excessive loads, or damage to structural components can all affect a scaffold’s stability.

The scaffold designer will be responsible for selecting the appropriate scaffolding and preparing a scaffold design for the job. They design the scaffold installation.

The scaffold designer should consider:

Where necessary, improved scaffold stability may be achieved by:

Scaffolds should be designed by a competent person, for example a person holding a relevant scaffolding high risk work licence.

Systems of work should be clear but flexible to meet changing circumstances as the work progresses. The system of work should provide for the assessment and control of any new risks arising from proposed changes to the work before they are implemented.

A documented safe system of work is an administrative control. For scaffolding work this could include consideration of:

A person who erects, alters or dismantles any scaffold must be competent to do the work safely.

A person undertaking scaffolding work must hold the relevant class of scaffolding high risk work license as required by the WHS Regulations. The scaffolding high risk work license classes are:

Basic scaffolding license—required for scaffolding work involving:

Intermediate scaffolding licence—required for scaffolding work involving:

Advanced scaffolding license—required for scaffolding work involving:

Where a person undertakes construction work they must have successfully completed general construction induction training.

A person who erects, alters or dismantles a scaffold where there is a risk of a person or object falling four metres or less from the platform or structure does not require a high risk work licence. This sort of work may involve tasks like erecting a small frame scaffold to repair the eaves of house or to paint a ceiling. These types of scaffolds are not generally used to provide a work platform at a height in excess of one storey or for use by many workers at once.

Where required, the work method to safely erect, use and dismantle a scaffold. It is not required a scaffolding plan will help identify ways to protect people who are:

For more complex scaffolds a scaffolding plan should be prepared by a competent person. In preparing a scaffolding plan the person should consult with a range of other people relevant to the work and workplace, for example:

The scaffolding plan should include a site layout plan and detail the elevations and sections of the scaffold. It should be kept at the workplace if reasonably practicable, or be readily accessible near the scaffold should it be required. The scaffolding plan should address:

The following safe work practices should be used when erecting a scaffold:

An example of scaffold erection is shown in Figure 2. In this example the scaffold is being erected against an existing building so guardrails are only needed on external faces. Access ladders and toe boards have been omitted for clarity.

Tie methods and spacing should be in accordance with the manufacturer, designer or supplier instructions. Consult the scaffold designer, manufacturer, supplier or an engineer if it is not practical

to position the ties in accordance with the instructions.

Control measures for tying scaffold include:

Working platforms, except suspended scaffolds, should have duty classifications and dimensions complying with the manufacturer’s information on loadings. Scaffold working platforms are generally rated as light, medium or heavy duty:

Each scaffold should be designed to carry the required number of working platforms and to support the dead and live loads. Where tools or materials are to be used or stored on working platforms, an unobstructed access width of at least 450 mm should be maintained.

Scaffold planks on working platforms should:

Lapped scaffold planks may sometimes be used to cover gaps around corners of scaffold. These planks should be safely secured. In some circumstances they may not need to be secured provided the following are met:

In these cases wind forces should be considered and if wind is a potential hazard then the lapping planks should be secured.

If using plywood sheets to cover gaps between scaffold bays the plywood sheets should be:

Metal planks lapped on other metal planks should be secured using fixings, for eg metal strapping. Tie wire or another system not structurally rated should not be used to secure planks on hop-up brackets.

More generally:

The following safe work practices should be used when dismantling a scaffold:

When altering a scaffold you should:

Procedures should be developed for inspecting and maintaining the scaffold and scaffolding to ensure the scaffold is safe to use and remains in a safe condition.

For suspended, cantilevered, spur and hung scaffolds and any other scaffold from which a person or thing could fall more than 4 metres:

Scaffolds with a fall risk of less than 4 metres should also be inspected before use and after any incident, repair, alteration or addition.

Inspecting scaffolds and scaffolding at a workplace is particularly important when the scaffold is in place for a long period of time. An example of a scaffold inspection checklist is at Appendix A.

Once a scaffold has been erected a handover inspection should be completed to check that the scaffold is safe to use. Where written confirmation from a competent person is required this usually takes the form of a handover certificate. An example is at Appendix B.

If alterations, repairs or additions to the scaffold are required a further inspection should be completed and a new handover certificate provided.

The handover certificate should be kept at the workplace until the scaffold has been dismantled.

Regular post-handover inspections should be completed once a scaffold is in use. How often these inspections are done will vary depending on the type and size of the scaffold, scaffold use, workplace conditions, the weather and any risk of scaffold collapse.

Scaffold inspections must be completed every 30 days for scaffolds with a fall risk of more than 4 metres. The designer or supplier of the scaffold should be consulted on the intervals for inspection when the scaffold is first installed.

If an inspection identifies a problem with the scaffold, access to the scaffold must be controlled and any necessary repairs, alterations and additions completed. Once the work is complete the scaffold must be inspected again. Where written confirmation from a competent person is required a new handover certificate should be provided.

Regular scaffold maintenance should also include inspections of stored scaffold components as well as those in use. Scaffolding stored in areas exposed to the weather can become corroded. Each item of scaffolding should be inspected before being incorporated into a scaffold.

Inspection records should be kept at the workplace or be readily accessible near the scaffold should they be required. Inspection records should include the location, comments, date and time of inspections, relevant design or specification reference and the person who carried out the inspection

The following should be considered to control risks associated with scaffolds and scaffolding work. More specific requirements apply to suspended, cantilevered, spur or hung scaffolds and a scaffold from which a person or thing could fall more than 4 metres.

No part of the scaffolding work should adversely affect the structural integrity of other buildings. You should ensure risks are controlled to prevent injury to people or damage to adjacent buildings or structures from the:

Electric lines whether overhead or underground can be a significant hazard. Construction work carried out on or near energised electrical installations or services is high risk construction work.

Safe entry and exit is required for workers when erecting, using and dismantling a scaffold. Common means of entry and exit include:

Stairs should be secured to the scaffold bay. If stairs cannot be self-secured to the scaffold they should be lashed. If not secured the designer or supplier should provide documentation showing the maximum amount of clearance allowed between the transom and the top and bottom of the stair module. The gap between the end of a stair module and a transom should be as small as possible. Large gaps can lead to stairs dislodging and falling when a load is placed onto it.

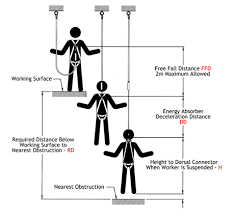

A risk to health and safety associated with a fall by a person from one level to another that is reasonably likely to cause injury to the person or any other person must be managed. Hazards that may increase the risk of falls include:

Passive engineering controls like handrails and edge protection can minimise the risk of a fall during work at height. Catch platforms can be used to minimise the distance a person could fall during work at height and also to catch falling objects.

Fall arrest systems should only be used during the following scaffold activities:

Falling object risk control measures include fall arrest platforms, overhead protective structures, perimeter containment screens and exclusion zones to eliminate or minimise the risk of falling objects.

Perimeter containment screens can be made of mesh, high quality shade cloth, timber, plywood, metal sheeting or other suitable material. Before using perimeter containment screening, consider other risks like conductivity of electricity and additional dead and live loads. For example, the extra wind loading on the scaffold should be considered when selecting a screening material and the framework supporting a screen must be able to support loads resulting from the screen.

Ladders may be used where entry to the working platform is needed by only a few people and where tools and equipment can be delivered separately to the working platform, for example by materials hoist, crane or a rope and gin wheel. Ladders used for entry to or exit from a scaffold should be:

Ground conditions should be stable and those doing the scaffolding work should be aware of any factors that may affect ground stability before the scaffold is erected or during its use.

Ground conditions should be assessed by a competent person to check the ground is stable and able to bear the most adverse combination of dead, live and environmental loads that can reasonably be expected during the period the scaffold is to be erected and dismantled and while it is in use.

Water and nearby excavations may lead to ground subsidence and the collapse of a scaffold. Any likely watercourse, for example a recently filled trench that has the potential to create a wash out under the scaffold base should be diverted away from the scaffold.

Click the below link to download more details about scaffolding safety

Work permits Below

Tool Box Talk Below

Scaffold-use of brace for guard rails

Checklist’s & More Below

Scaffolding staging tower for concr pump

Scaffolding construction part-2

Scaffolding construction part-1

Dos and Don ts – Scaffolding: