Determine preventive measures:

The final stage in a JSA is to determine ways to eliminate or control the hazards identified. The generally accepted measures, in order of preference, are:

1. Eliminate the hazard

This is the most effective measure. These techniques should be used to eliminate the hazards:

- Choose a different process

- Modify an existing process

- Substitute with less hazardous substance

- Improve environment (ventilation)

- Modify or change equipment or tools

2. Contain the hazard

If the hazard cannot be eliminated, contact might be prevented by using enclosures, machine guards, worker booths or similar devices.

3. Revise work procedures

Consideration might be given to modifying steps which are hazardous, changing the sequence of steps, or adding additional steps (such as locking out energy sources).

4. Reduce the exposure

These measures are the least effective and should only be used if no other solutions are possible. One way of minimizing exposure is to reduce the number of times the hazard is encountered. An example would be modifying machinery so that less maintenance is necessary. The use of appropriate personal protective equipment may be required. To reduce the severity of an accident, emergency facilities, such as eyewash stations, may need to be provided.

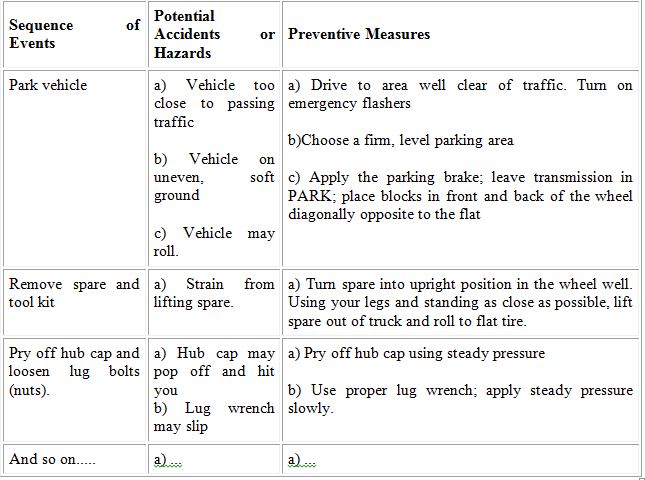

In listing the preventive measures, do not use general statements such as “be careful” or “use caution”. Specific statements which describe both what action is to be taken and how it is to be performed are preferable. The recommended measures are listed in the right hand column of the worksheet, numbered to match the hazard in question. For example:

How should I make the information available to everyone else?

JSA is a useful technique for identifying hazards so that workers can take measures to eliminate or control hazards. Once the analysis is completed, the results must be communicated to all workers who are, or will be, performing that job. The side-by-side format used in JSA worksheets is not an ideal one for instructional purposes. Better results can be achieved by using a narrative-style communication format. For example, the work procedure based on the partial JSA developed as an example in this document might start out like this:

1. Park vehicle.

a) Drive vehicle off the road to an area well clear of traffic, even if it requires rolling on a flat tire. Turn on the emergency flashers to alert passing drivers so that they will not hit you.

b) Choose a firm and level area for parking. You can jack up the vehicle to prevent rolling.

c) Apply the parking brake, leave the transmission in PARK, place blocks in front and back of the wheel diagonally opposite the flat. These actions will also help prevent the vehicle from rolling.

2. Remove spare and tool kit.

a) To avoid back strain, turn the spare up into an upright position in its well. Stand as close to the trunk as possible and slide the spare close to your body. Lift out and roll to flat tire.

3. Pry off hub cap, loosen lug bolts (nuts).

a) Pry off hub cap slowly with steady pressure to prevent it from popping off and striking you.

b) Using the proper lug wrench, apply steady pressure slowly to loosen the lug bolts (nuts) so that the wrench will not slip, get lost or and hurt your knuckles.

4. And so on.