A forklift is also known as a lift truck essentially because it’s a truck that can lift loads using a set of forks. A forklift can be used in numerous places such as warehouses, factories, farms, shipping yards and much more. There are many types of forklifts which can be called a variety of different names; in this case we will use the basic names of the forklifts when describing their capabilities.

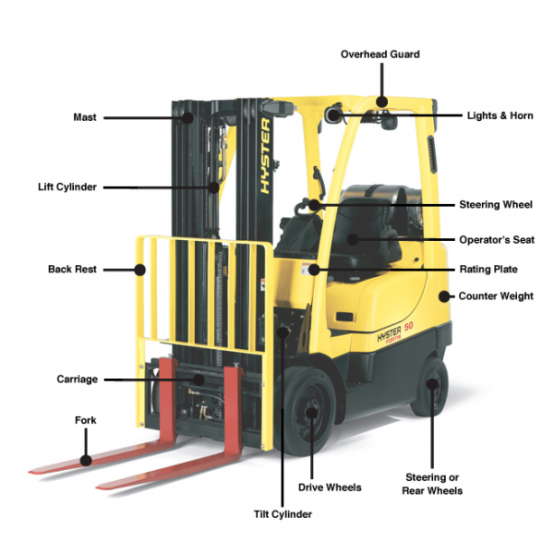

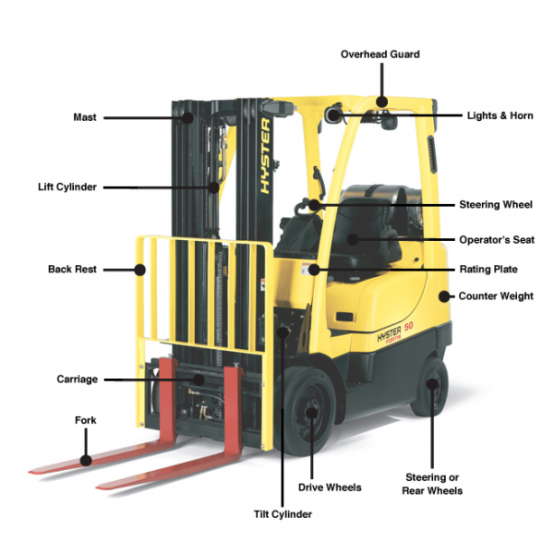

- Mast: The mast is the vertical support that permits raising and lowering the load.

- Carriage: A support structure where the forks are attached or mounted.

- Back Rest: Attached to the carriage and prevents the load shifting backwards, it protects the mast cylinders hoses as well as preventing any goods falling through the mast and hitting the operator.

- Fork (Tynes): The cantilevered arms attached to the load carriage, that engage the load.

- Lift Cylinder: Controls the amount by which the mast structure, forks and carriage may be raised or lowered in the vertical.

- Overhead Guard: A framework/roof, providing overhead protection for the operator from falling objects.

- Tilt Cylinder: Controls the amount by which the mast structure, forks and carriage may be tilted beyond the vertical position, forward or backward.

- Rating Plate: This is used to inform users of the maximum load a forklift can legally carry.

- Counter Weight: The weight installed by the manufacturer to give stability to the machine under load.

Types of Forklifts:

- Industrial Reach Forklift Trucks

- Industrial Counterbalance Forklifts

- Rough Terrain Forklifts

- Industrial Side Loader Forklifts

- Telescopic Handler Forklifts

- Pedestrian Operated Pallet Trucks

Industrial Reach Forklift Trucks:

Industrial reach forklift truckare renowned for their extended lift height, making them ideal in any warehousing situation with high rise storage pallet racking. There are different types of reach forklift truck that are best suited to a range of scenarios:

Industrial reach forklift truckare renowned for their extended lift height, making them ideal in any warehousing situation with high rise storage pallet racking. There are different types of reach forklift truck that are best suited to a range of scenarios:

Stand-up trucks are the most common and are often used where there’s only one load per bay. The two forks on the front of the truck slide underneath palletised loads, to lift and transport safely.

Double-deep trucks are similar, but with longer forks, making them perfect for areas where multiple pallet loads are stored in each bay as they will reach right to the back of the bay. Straddle trucks also have long forks to slide under the load, while they also have the ability to grip onto the edges for increased stability and ease of access. This is ideal if you have multiple loads in one bay that you can access from different angles, as the truck can grab loads further back.

Industrial Counterbalance Forklifts:

Industrial counterbalance forklifts are the most common trucks used in indoor warehouses and stores, although they can be used outdoors, on stable, even surfaces. They offer straightforward operation and have dual forks at the front of the truck that lift and transport the loads.

Industrial counterbalance forklifts are the most common trucks used in indoor warehouses and stores, although they can be used outdoors, on stable, even surfaces. They offer straightforward operation and have dual forks at the front of the truck that lift and transport the loads.

There are different types available, including three-wheel models that provide better manoeuvrability, making them perfect for narrow aisles.

Rough Terrain Forklifts:

For outdoor construction and with difficult terrain, a rough terrain forklift is ideal. It has inflatable tyres with thicker threads, allowing stability on uneven ground, as well as a more powerful engine so it can reach higher speeds, and better manoeuvrability, making them must more robust and durable.

For outdoor construction and with difficult terrain, a rough terrain forklift is ideal. It has inflatable tyres with thicker threads, allowing stability on uneven ground, as well as a more powerful engine so it can reach higher speeds, and better manoeuvrability, making them must more robust and durable.

This means that they are perfect for transporting heavy loads across rugged terrain, with some models handling up to 3 tonnes per load. The carefully calibrated counterbalance at the back of the truck prevents overbalancing, with it being easily operated in mud, ice or even snow.

Industrial Side Loader Forklifts:

![]()

Side loader forklift trucks are ideally suited to working in narrow aisles. This is because the forks are mounted to the side of the truck and can pick up wide or long loads that would be awkward or inaccessible with a straight forward forklift.

There are two main types of side loader forklifts, the enclosed cab that is most commonly used outdoors, and a stand up version that is more suited to indoor tasks. There’s also a multi-way version, where the wheels all rotate by 90°, allowing ease of transportation in any direction.As a result, they are especially useful for lifting and transporting tubing, pipes and sheet materials safely and efficiently.

Telescopic Handler Forklifts:

Telescopic handler forklifts are ideal for use in agriculture and all kinds of industry that require high lifting. They offer a whole range of features that make them much more useful in a range of situations, so much so that they are often thought of as small cranes, rather than forklift trucks.

Telescopic handler forklifts are ideal for use in agriculture and all kinds of industry that require high lifting. They offer a whole range of features that make them much more useful in a range of situations, so much so that they are often thought of as small cranes, rather than forklift trucks.

Telescopic handlers have the additional advantageof a single telescopic boom that allows the truck to become a much more powerful and flexible piece of machinery. There are a number of practical attachments available, including a lift table, bucket, pallet fork and muck grabber.

These attachments, and the ability to extend the lifting capabilities with front outriggers, enable the tele-handler to complete work at heights that normal forklifts can’t reach.

Pedestrian Operated Pallet Trucks:

Pedestrian operated lift trucks and pallet trucks are most commonly used in warehouses and storage facilities for the easy transportation of pallets. All pedestrian operated trucks have forks that slide beneath the pallet and use a hydraulic jack to lift the load from the ground for easy manoeuvrability.

Pedestrian operated lift trucks and pallet trucks are most commonly used in warehouses and storage facilities for the easy transportation of pallets. All pedestrian operated trucks have forks that slide beneath the pallet and use a hydraulic jack to lift the load from the ground for easy manoeuvrability.

There’s a wide variety of styles and designs available, some capable of moving loads of 5000lbs, but the main difference is between the lift and pallet trucks.

The pallet truck is simply for moving loads from one place to another at ground level, but it has limited reach, while the lift truck is more complex and is capable of transporting and lifting a palletised load onto a higher level or for stacking loads on top of each other.

Passengers Not Allowed

Pedestrian Awareness

Pedestrian Responsibilities

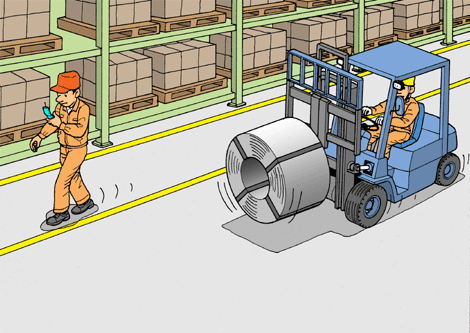

Pedestrians and Forklifts

Preshift Inspections

The Human Counterweight

Passengers Not Allowed

Pedestrian Awareness

Pedestrian Responsibilities

Pedestrians and Forklifts

Preshift Inspections

The Human Counterweight

Industrial reach forklift truckare renowned for their extended lift height, making them ideal in any warehousing situation with high rise storage pallet racking. There are different types of reach forklift truck that are best suited to a range of scenarios:

Industrial reach forklift truckare renowned for their extended lift height, making them ideal in any warehousing situation with high rise storage pallet racking. There are different types of reach forklift truck that are best suited to a range of scenarios: Industrial counterbalance forklifts are the most common trucks used in indoor warehouses and stores, although they can be used outdoors, on stable, even surfaces. They offer straightforward operation and have dual forks at the front of the truck that lift and transport the loads.

Industrial counterbalance forklifts are the most common trucks used in indoor warehouses and stores, although they can be used outdoors, on stable, even surfaces. They offer straightforward operation and have dual forks at the front of the truck that lift and transport the loads. For outdoor construction and with difficult terrain, a rough terrain forklift is ideal. It has inflatable tyres with thicker threads, allowing stability on uneven ground, as well as a more powerful engine so it can reach higher speeds, and better manoeuvrability, making them must more robust and durable.

For outdoor construction and with difficult terrain, a rough terrain forklift is ideal. It has inflatable tyres with thicker threads, allowing stability on uneven ground, as well as a more powerful engine so it can reach higher speeds, and better manoeuvrability, making them must more robust and durable. Telescopic handler forklifts are ideal for use in agriculture and all kinds of industry that require high lifting. They offer a whole range of features that make them much more useful in a range of situations, so much so that they are often thought of as small cranes, rather than forklift trucks.

Telescopic handler forklifts are ideal for use in agriculture and all kinds of industry that require high lifting. They offer a whole range of features that make them much more useful in a range of situations, so much so that they are often thought of as small cranes, rather than forklift trucks. Pedestrian operated lift trucks and pallet trucks are most commonly used in warehouses and storage facilities for the easy transportation of pallets. All pedestrian operated trucks have forks that slide beneath the pallet and use a hydraulic jack to lift the load from the ground for easy manoeuvrability.

Pedestrian operated lift trucks and pallet trucks are most commonly used in warehouses and storage facilities for the easy transportation of pallets. All pedestrian operated trucks have forks that slide beneath the pallet and use a hydraulic jack to lift the load from the ground for easy manoeuvrability.