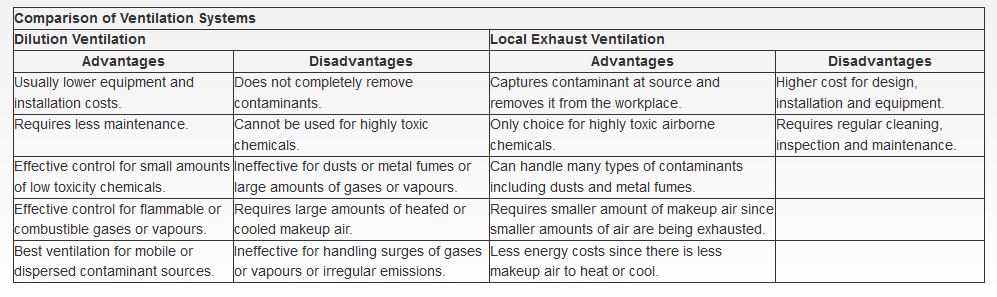

Which type of ventilation system is best for my workplace:

All industrial ventilation systems, when designed properly, should be able to provide long-term worker protection. The two types of ventilation, dilution and local exhaust, are compared in the following table.

limitations of any ventilation system:

Some limitations include:

- The systems deteriorate over the years because of to contaminant build-up within the system, especially filters.

- Require ongoing maintenance.

- Regular and routine testing is needed to identify problems early and implement corrective measures.

- Only qualified persons should make modifications to a ventilation system to make sure the system continues to work effectively.

The following is an example of changes that can affect how a system works:

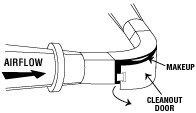

Figure 7

Adding a duct branch

A hood and branch are added to an existing duct. The local exhaust ventilation pulls air into the system from the new location, which will reduce the airflow from other locations that are further away from the exhaust fan. Again, airflow will all be affected. The result is that the system will plug more rapidly and the air flows at the other hoods may not be adequate enough to remove contaminants.

Measures for dilution ventilation rates:

Air Changes per minute (ACM) [or air changes per hour (ACH)] is generally used as a way to measure the dilution ventilation rate. Air exchange rate means replacing the entire volume of air in the work space in one minute or one hour. The following formula can be used to determine the air exchange rate:

For example if the air flow rate required in a work space which is 40 feet long, 40 feet wide and 12 feet high, volume of the work space is 40 x 40 x 12 = 19,200 cubic feet.

Air flow rate required per ACH = 19,200 / 60 = 320 cfm

Or, air flow rate required per ACM = 19,200 cfm

Or, if the ceiling height is 20 feet high then the room volume is 40 feet X 40 feet X 20 feet high= 32,000 cubic feet and the required air flow rate will be as follows:

Air flow rate required per ACH = 32,000 / 60 = 533 cfm

Or, air flow rate required per ACM = 32,000 cfm

The required air change rate is sometimes given in ventilation regulations and ventilation design standards. For example, a flammable storage room requires six air changes per hour according to US OSHA requirements. The Canadian National Building Code (NBC) requires residential houses to mechanical ventilation system capable of providing at least one half (0.5) air changes per hour during the heating season to avoid chimney back drafting.

However, air changes per hour (or minute) may not be an appropriate measure for ventilation criteria when controlling certain hazards, heat and/or odors. Ventilation should be determined on the amount of contaminant generated, and the toxicity of that contaminant (not just the size of the room).

Design standards available:

Although there are not many specific government codes and regulations, there are many recommended standards. The important ones are described below (in no particular order):

Please see the OSH Answers document Industrial Ventilation – Glossary of Common Terms for a description of the acronyms.

Ontario Occupational Health and Safety Act – Regulation 851 for Industrial Establishments (section 127 & 128) mentions general requirements for adequate ventilation and replacement air.

British Columbia O.H.& S Regulation – BC Regulation 296/297 Part 5.60-5.71 gives the detailed requirements for dilution ventilation, LEV, make-up air, discharged air and re circulation of discharged air.

OSHA – This US Government agency has promulgated a few ventilation standards, e.g., the four standards in 29CFR1910.94 dealing with local exhaust systems. OSHA’s construction standards in 29CFR1926 contain ventilation standards for welding. Such ventilation systems are “required,” but OSHA usually does not consider its ventilation standards violated unless exposure standards are also violated.

NIOSH – This US Government research organization has published a number of useful ventilation documents, including publications on foundry ventilation, re circulation, and push – pull hoods.

AMCA – This US trade association has developed standards and testing procedures for fans. It has a number of useful publications related to fan selection, testing, troubleshooting and certification (e.g., AMCA 201).

ASHRAE – This US based society of heating and air conditioning engineers has produced a number of standards related to indoor air quality (IAQ), filter performance and testing comfort, and HVAC systems.

ANSI -This US based consensus standards setting organization has produced several important standards on ventilation including paint spray booths, grinding exhaust hoods, open sun tank exhausts and laboratory ventilation.

ACGIH – The ACGIH Industrial Ventilation Committee publishes the manual of recommended practice for industrial ventilation. The Manual has been recognized worldwide a useful source of information on all aspects of IVS.

SMACNA – This US association of sheet metal contractors and suppliers sets standards for ducts and duct installation.

NFPA – This US based fire protection association has produced a number of recommendations (which become requirements when adopted by local fire agencies), e.g. NFPA 45 lists a number of ventilation requirements for Lab Fume hood use.

BUILDING CODES – There are building codes set or adopted by almost every city, county and municipality. All industrial buildings have to be built to these codes in order to have a building accepted. However, most have little direct reference to industrial ventilation, but these codes need to be checked.

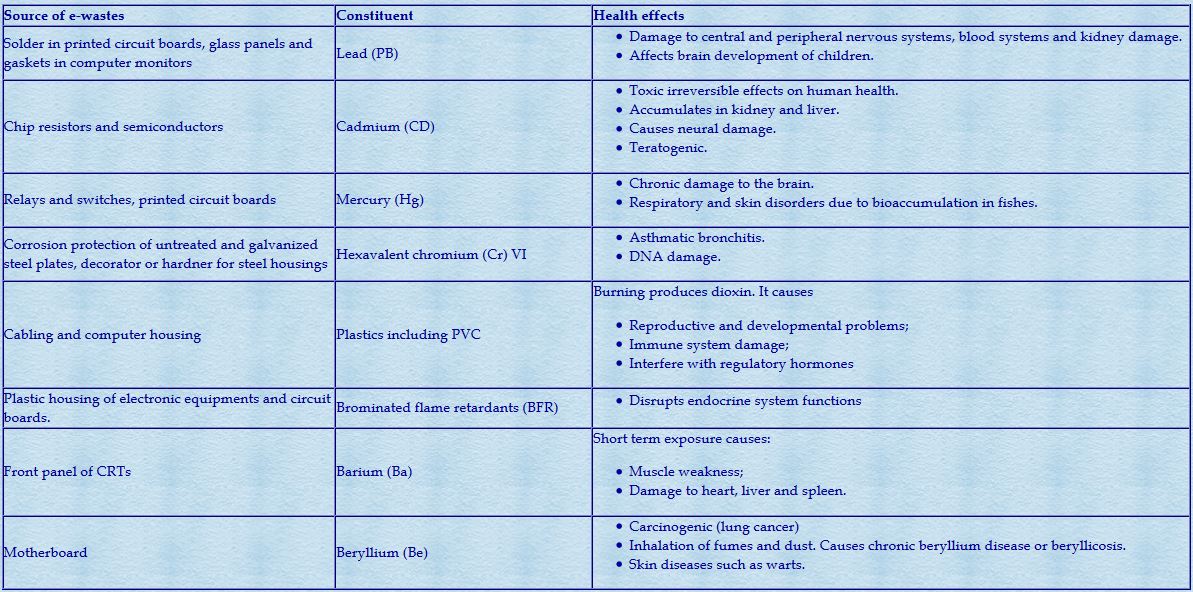

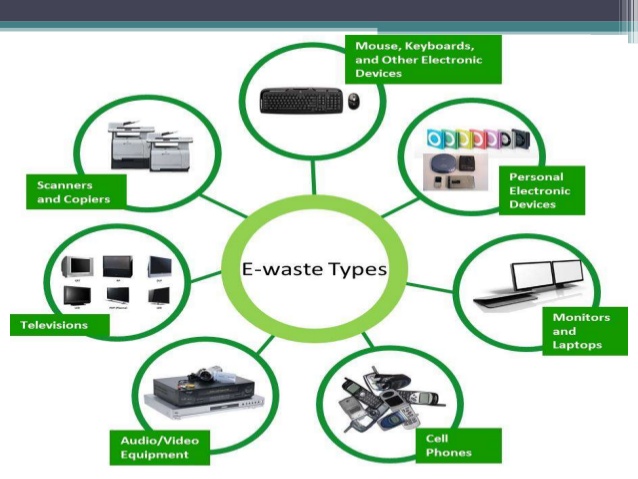

mismanagement has led to new problems of contamination and pollution. The technical prowess acquired during the last century has posed a new challenge in the management of wastes. For example, personal computers (PCs) contain certain components, which are highly toxic, such as chlorinated and brominated substances, toxic gases, toxic metals, biologically active materials, acids, plastics and plastic additives.The hazardous content of these materials pose a environmental and health threat. Thus proper management is necessary while disposing or recycling ewastes.

mismanagement has led to new problems of contamination and pollution. The technical prowess acquired during the last century has posed a new challenge in the management of wastes. For example, personal computers (PCs) contain certain components, which are highly toxic, such as chlorinated and brominated substances, toxic gases, toxic metals, biologically active materials, acids, plastics and plastic additives.The hazardous content of these materials pose a environmental and health threat. Thus proper management is necessary while disposing or recycling ewastes.