Barricades are something you see everywhere you go – from banks to furniture stores to factories. They can be as simple as rope strung across an opening, or a welded framework protecting people from an open manhole.

Most of these barricades are just guides to maintain an orderly flow, such as poles with banners connected together in a bank. Other barriers warn people to stay out of potentially dangerous situations, such as road cones at a construction site.

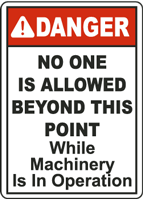

When it comes to workplace safety, barricades are a much more serious matter. They are not just suggestions; barriers are there to save your life.

The Occupational Safety and Health Administration (OSHA) defines “barricade” as “an obstruction to deter the passage of persons or vehicles.”

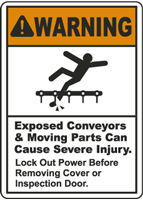

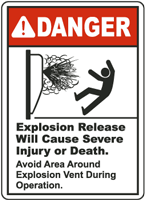

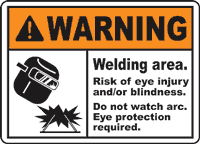

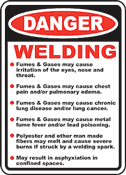

Exposed wires, moving machinery and high temperature valves are just a few of the potential dangers requiring barricades.

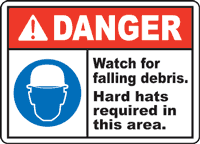

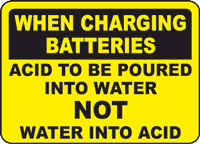

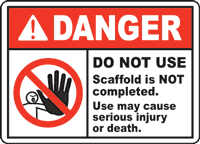

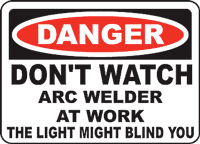

Many people do not even recognize the danger behind the barricade. Idiot-proofing should be your goal with barricades – be sure to include signs, warning lights and instructions if something should go wrong.

Hundreds of barricade products are available on the market today, such as barricade tape and machine guards.

You can also make your own barricades; they don’t have to be pretty, as long as they do the job. A barricade can be as basic as wooden two-by-four frameworks or as fancy as prefab tracks with all the accessories.

Regulatory bodies such as OSHA, ANSI and various levels of government have rules for some of these situations that require barricades (especially anything traffic-related), but not all. Common sense and workplace experience will have to drive most of your barricade best practices.

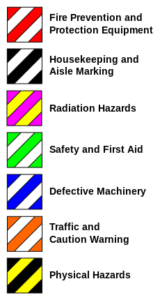

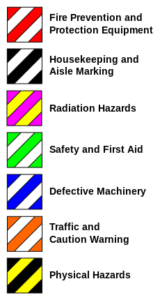

Barricade tape colors speak louder than words

OSHA regulations specify color coding of barricades, but that is as far as they go. The size, material and weight of barricade tape are up to the manufacturer.

Barricade tape colors, as decreed by OSHA, are as follows:

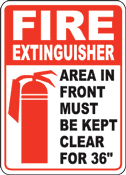

| Red / white for Fire Prevention and Protection Equipment

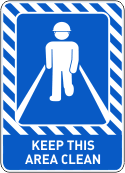

Black / white for Housekeeping and Aisle Marking

Magenta / yellow for Radiation Hazards

Green / white for Safety and First Aid

Blue / white for Defective Machinery

Orange / white for Traffic and Caution Warning

Black / yellow for Physical Hazards

|

|

While the colors have been chosen for you, the wording on your barricade tape has not. Hundreds of versions of barricade tape messages have been produced in dozens of languages. You can even buy barricade tape without wording or markings at all. (Special orders of barricade tape are no problem, but like anything, you’ll need to order a certain volume to bring the cost down.)

The marketplace seems to have standardized on three-inch-wide tape by 1,000 feet long for disposable tapes. Other sizes exist, such as two, four and six-inch.

The normal tape configuration is two to four mil thick, non-adhesive and made from polyethylene. Dispensers, boxes and clips are some of the accessories for these tapes.

Reusable tapes are normally much thicker (up to 10 mil thick) and made from either polypropylene or nylon.

Certain industries have their own needs for special tape, such as heavy paper tape used in paper and chemical plants.

Biodegradable tapes are increasing in use for those hard-to-reach places.

Tape variations exist for special situations or industry-specific problems, such as the police or military.

Whether reflective or normal, fluorescent or plain, sticky-backed or non-adhesive – barricade tapes are likely the most cost-effective safety aid you will ever buy.

Safety Color Coding Labels and Tape

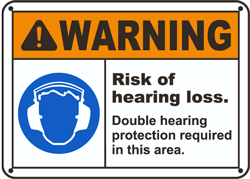

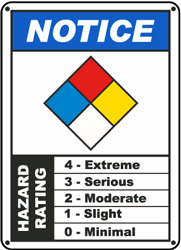

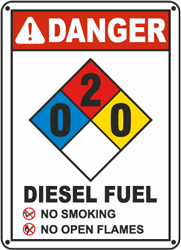

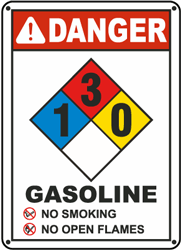

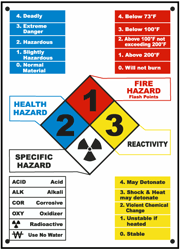

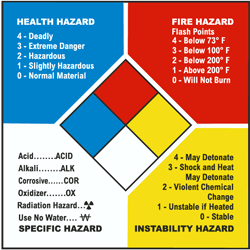

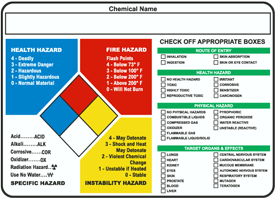

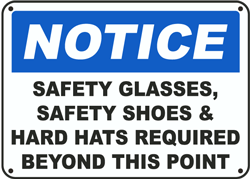

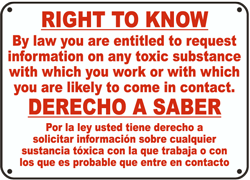

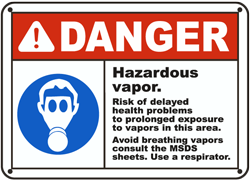

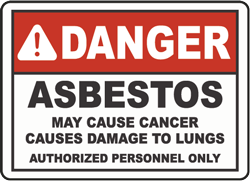

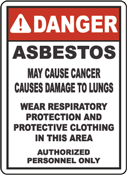

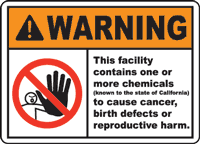

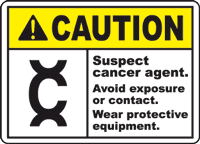

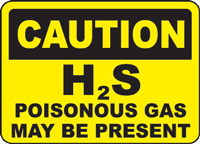

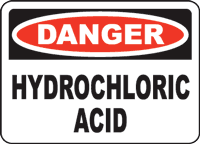

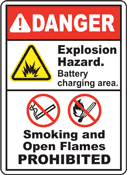

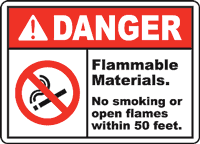

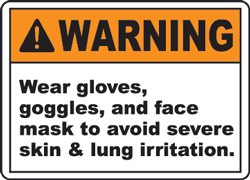

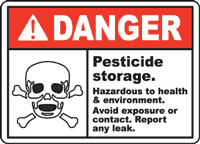

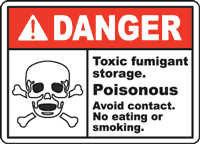

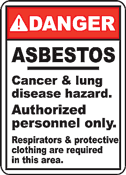

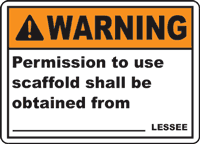

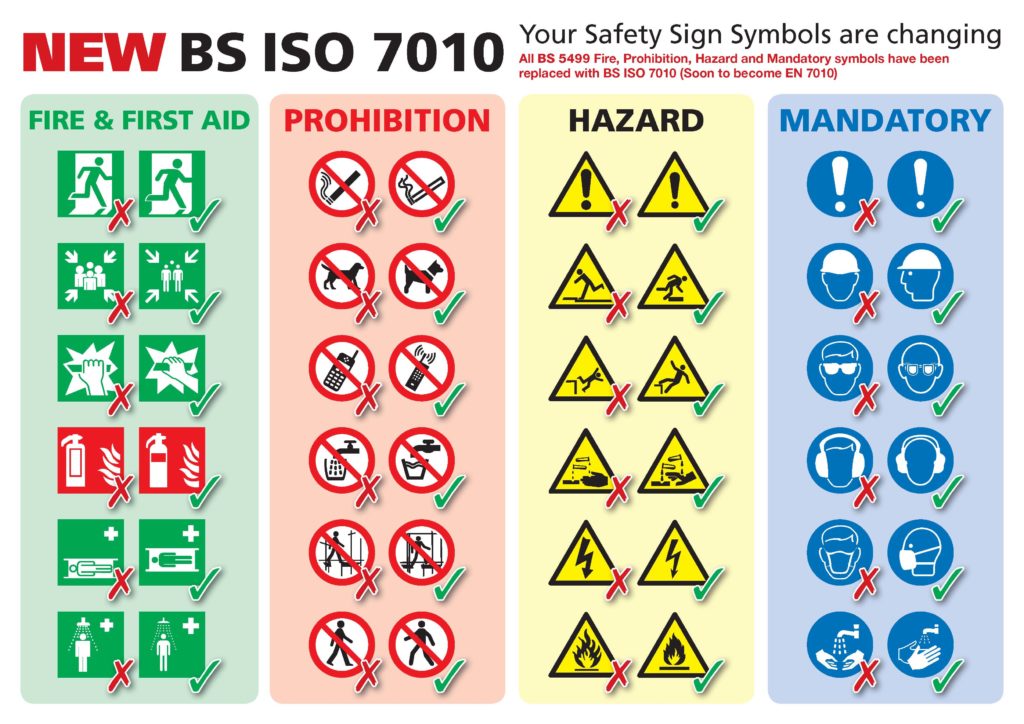

The Occupational Safety and Health Administration (OSHA) requires that workplace hazards be marked to alert employees to dangers that exist at a facility or worksite. Depending on the specific situation, different regulations could apply.

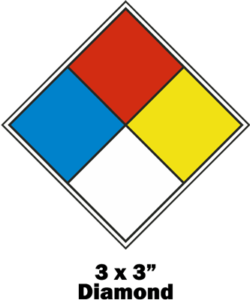

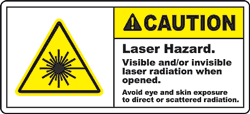

OSHA requirements are often non-prescriptive in regards to size, color and wording of markings. To help provide uniformity among organizations and industry, the American National Standards Institute (ANSI) and the National Electrical Manufacturers Association (NEMA) have developed and published the ANSI/NEMA Z535 series of standards for safety signs and colors. The color(s) of the labels and tape identify the type of hazard, which helps the employee identify the level of severity. The intent is to reduce the possibility of accidents and injuries. OSHA outlines the color code for marking physical hazards in 29 CFR 1910.144. In applications where there are no specific OSHA standards that apply, then the ANSI/NEMA Z535 standards, which are national consensus standards, are followed.

The ANSI/NEMA Z535 series is composed of six documents and a color chart:

- ANSI/NEMA Z535 Color Chart

- ANSI/NEMA Z535.1 Safety Colors

- ANSI/NEMA Z535.2 Environmental Facility and Safety Signs

- ANSI/NEMA Z535.3 Criteria for Safety Symbols

- ANSI/NEMA Z535.4 Product Safety Signs and Labels

- ANSI/NEMA Z535.5 Safety Tags and Barricade Tapes (for Temporary Hazards)

- ANSI/NEMA Z535.6 Product Safety Information in Product Manuals, Instructions and Other Collateral Materials

The following chart represents the color codes of both ANSI/NEMA Z535.1-2006 (R2011) and OSHA:

| COLOR |

MEANING |

APPLICATION |

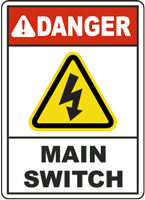

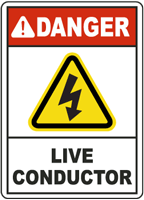

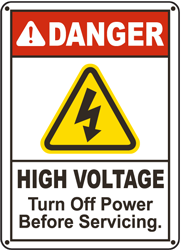

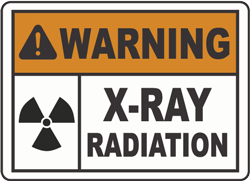

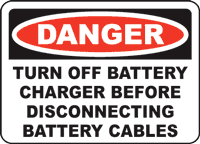

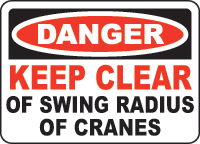

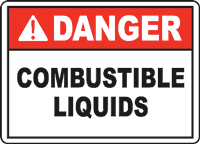

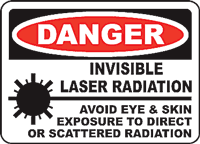

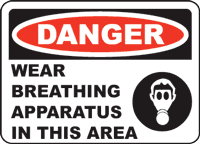

| Red |

Danger |

Safety cans and signs. |

| Stop |

Emergency stop bar or button on machinery. Identification of fire equipment. |

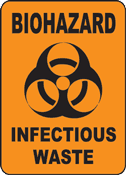

| Fluorescent Orange, Orange-Red |

Biosafety |

Labels and containers for blood and infectious waste. (Warning labels must be fluorescent orange or orange-red with the biosafety symbol in a contrasting color.) |

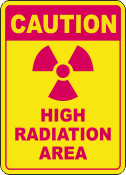

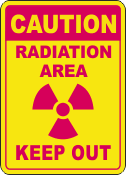

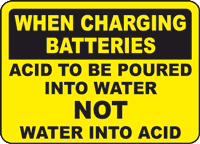

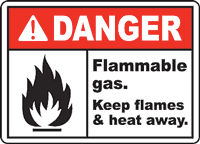

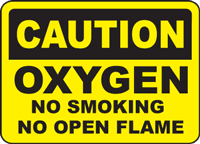

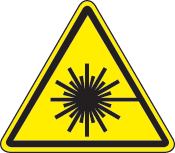

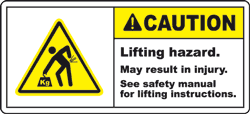

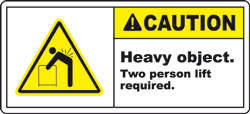

| Yellow |

Caution |

Tripping, falling and striking hazards. “Flammable, Keep Fire Away” labels on cabinets. Safety cans and containers for explosives, corrosives or unstable materials. |

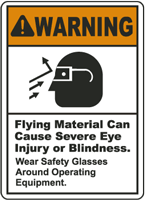

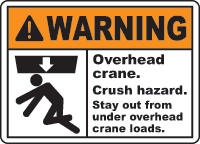

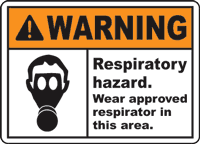

| Orange |

Warning |

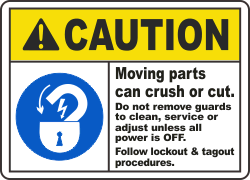

Parts of machinery or energized equipment that may cut, crush or otherwise injure. Inside of transmission guards for pulleys, gears, etc. |

| Green |

Safety |

Location of first aid equipment. Location of safety equipment, respirators, safety showers, etc. |

| Blue |

Information |

Signs and bulletin boards. Specific railroad warnings against starting, using or moving equipment being repaired. |

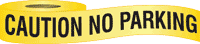

| Black, White, Yellow or Combination of Black with White or Yellow |

Boundaries |

Traffic or housekeeping markings. Stairways, directions and borders. |

| Magenta or Purple on Yellow |

Radiation Caution |

X-ray, alpha, beta, gamma, neutron and proton radiation. |

Marking Physical Hazards

Several regulations refer to markings depending on the situation. The following are common situations where color-coded labels and tapes are needed. State and local codes may require more specific markings.

- Compressed gas cylinders (29 Code of Federal Regulations (CFR) 1910.253). The contents of the cylinder—either the chemical or trade name—must be labeled, stenciled or stamped on the shoulder of the cylinder.

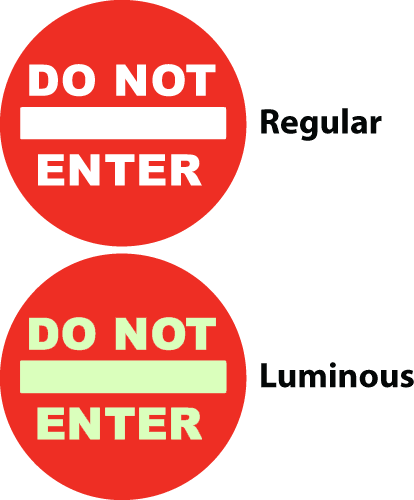

- Confined spaces (29 CFR 1910.146). A workplace containing confined spaces must be identified by danger signs or other effective means of identifying the existing confined spaces, their locations and the dangers they pose, 29 CFR 1910.146).

- Exits (29 CFR 1910.37). Signs must identify exit locations. “EXIT” signs with an arrow showing the direction of the nearest exit must be placed in locations where an exit is not immediately observable. Doors and passageways that are not exits must also be marked.

- Eyewash/shower stations (ANSI Z358.1-2014). The locations of eyewashes and showers must be identified.

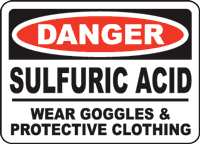

- Hazardous chemicals (29 CFR 1910.1200). Appropriate labels and warnings on chemical containers in the workplace are required, 29 CFR 1910.1200).

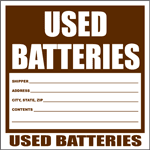

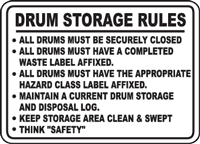

- Hazardous waste (40 CFR Part 262). Facilities accumulating hazardous waste on site must label containers as “Hazardous Waste” and include the accumulation start date. Containers that are transported must be labeled in accordance with Department of Transportation Hazardous Materials Regulations).

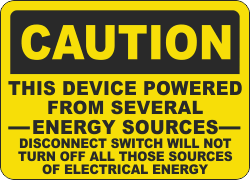

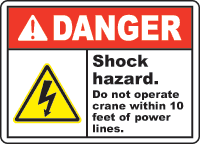

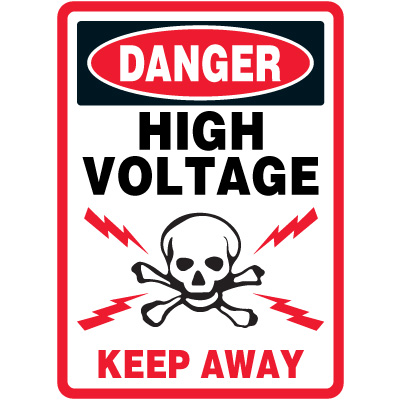

- High voltage (29 CFR 1910.305). Outside covers for pull and junction boxes must be permanently marked “High Voltage.”

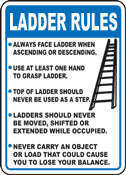

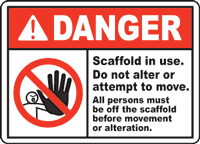

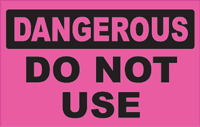

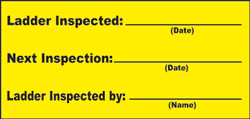

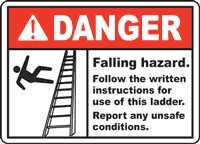

- Ladders (29 CFR 1910.25). Defective ladders must be taken out of service and marked “Dangerous—Do Not Use”.

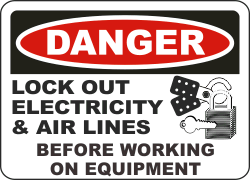

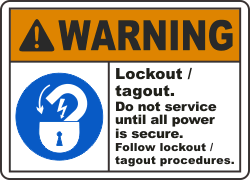

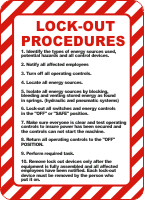

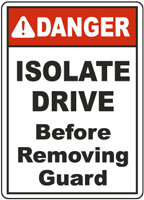

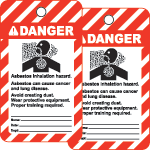

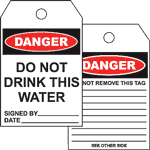

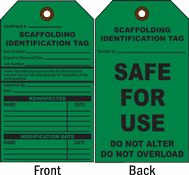

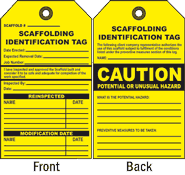

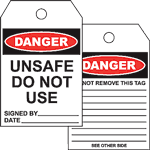

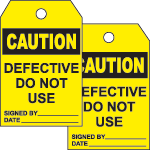

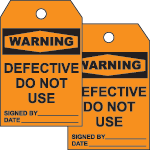

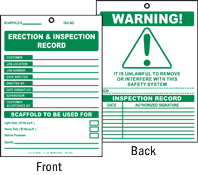

- Lockout/tagout (29 CFR 1910.147). Lockout and tagout devices need to be standardized within a facility in terms of size, color, shape, print and format. Tagout devices need to warn against hazardous conditions if equipment is energized. Appropriate legends on the tagout devices include: Do Not Start, Do Not Open, Do Not Operate, Do Not Close and Do Not Energize 29 CFR 1910.147).

- Machine guarding (29 CFR 1910.213). Radial saws: The direction of rotation must be marked on the hood. Additionally, a permanent label, at least 1-1/2 inches by 3/4 inch that reads “Danger: Do not rip or plough from this end” must be placed at the rear of the guard.

- Permanent aisles and passageways (29 CFR 1910.176). Sufficient clearances need to be allowed for mechanical equipment handling, loading docks and doorways. To help keep areas clear, such passageways must be clearly marked. Striped or solid floor tapes are commonly used to mark off such areas. The color of tape used depends on degree of hazard.

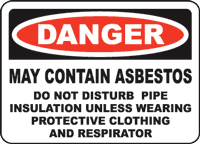

- Pipe markings (ANSI/ASME A13.1-2007). ANSI/ASME requires that pipes be marked with a legend indicating the name of the contents and arrows showing the direction of flow of the material. A color is used in combination with the legend to identify the characteristic hazards of the contents. The label needs to be applied close to valves, flanges, branches, changes in direction and wherever pipes pass through walls. Following is the classification of materials and designated colors:

- Fire quenching fluids: White on red background

- Toxic and corrosive fluids: Black lettering on orange background

- Flammable fluids: Black on yellow background

- Combustible fluids: White on brown background

- Potable, cooling, boiler feed and other water: White on green background

- Compressed air: White on blue background

Commonly Asked Questions

Q. What is the difference between OSHA and ANSI requirements for marking hazards?

A. OSHA outlines markings for Danger and Caution hazards in 29 CFR 1910.144. ANSI also defines Danger and Caution, but further describes Warning and other color designations in ANSI Z535.1-2006 (R2011).

Q. Are arrows required in addition to marking pipes?

A. Yes. ANSI/ASME A13.1-2007 states that arrows shall be used on either end or both ends of the label to show the direction of flow. Arrows should be placed every 50 feet on straight runs, on both sides of wall, floor or ceiling penetrations, and near valves, flanges and changes in pipe direction, and at any line entry or re-entry point.

Q. Which pipes need to be marked?

A. According to ANSI/ASME A13.1-2007, pipe systems include pipes of any kind must be marked. They are defined as conduits for transporting gases, liquids, semi-liquids or fine particle dust.

Sources

29 CFR 1910.144, Safety Color Code for Marking Physical Hazards

29 CFR 1910.145, Specifications for Accident Prevention Signs

ANSI/NEMA Z535.1-2006 (R2011), Safety Color Code

ANSI/NEMA Z535.2-2011, Environmental and Facility Safety Signs

No dogs except assistance dogs

No dogs except assistance dogs warning you are entering an area where tobacco smoke may be present

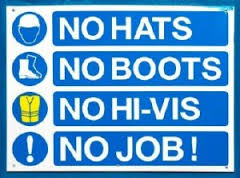

warning you are entering an area where tobacco smoke may be present High Visibility jacket must be worn

High Visibility jacket must be worn